About Us

Company Profile

Heril established in 2021, but our team is not new to this industry, on the contrary, we have been working in this field for over 24 years. The new economy needs fresh blood, to respond to the call of the times, we build up a state of the art manufacturing facility, research and development laboratory and a product development team, we offer a comprehensive range of services to meet the needs of brands and retailers globally.

With long-standing experience in product development, packaging design, retail and manufacturing we know how to find the perfect balance between product mix, positioning and retail pricing. Besides, we are open for all new things and actively explore them, keep abreast of market demands and deliver value.

Laboratory

Heril’s R&D laboratory is equipped with an imported 100-grade ultra-clean operating platform, and it adopts advanced experimental techniques for testing. In our own laboratory, we can test appearance, color, odour, stability, PH value, viscosity, foam height and microbiological testing, active substance test.

Rigorous microbiological testing is the most important means to ensure the microscopic quality of products.

Purification Unit

There is an advanced air circulation system in the standards as a 100000-grade GMP workshop to ensure that there is no pollution during production. The system realizes intelligent operation, and with the mobile terminal, it can monitor the running status of the circulation system real time.

The strict processing and quality management ensure us to provide satisfied products to our customers all over the world.

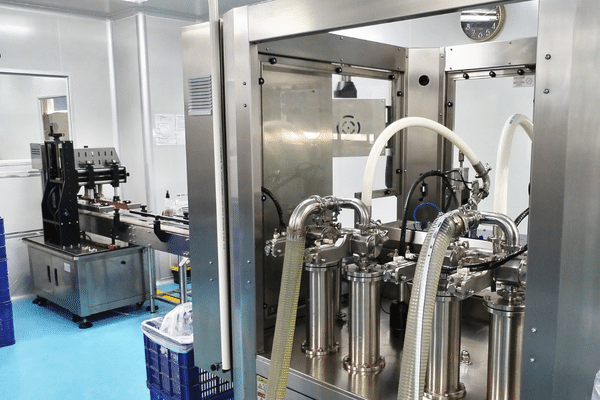

Filling Equipment

We have state-of-the-art production facilities, each month our automatic filling production lines roll out 250,000 bottles.

In addition, we also have semi-automatic filling lines for orders of small quantities, which can meet diversified production requirements and provide customers with customized services.

Liquid Production Facilities

The introduction of new equipment has increased the overall production capacity of the factory, enabling us to serve more customers while ensuring efficient production.

The combination of different emulsifying pots and mixing pots ensures a daily liquid output of 10 tons in the factory, which fully meets the needs of customers. During the transportation of raw materials, we transport them separately in different storage tanks to minimize the possibility of secondary pollution.

Water Treatment Equipment

We implement strict control on water sources. While introducing reverse osmosis water purifier, we further adopt secondary purification to ensure that all water meets the quality standards of medical water.

Assembling Workshop

Our assembling production workshop can work efficiently and fulfill our customers’ orders in good quality and on time.

Submit your custom request now

Our engineers will contact you within 24 hours